SPOILER ALERT!

bitumen infiltration quality 80/100- Iran Bitumen 80/100- Bitumen 80/100

5% of bitumen is utilized for securing and also protecting purposes in different building products such as rug ceramic tile support and paint. Tightness of bitumen is the utmost bitumen exporters sensation for bitumen, while eating in mouth was the earliest mode of testing bitumen; thus the examination temperature back then was 37 ° C( which is the temperature level of human body).

These seeps are locations where nonrenewable fuel sources and oil items leakage out of the Planet as opposed to being trapped deep listed below the ground. Furthermore bitumen uae manufacturers, bitumen is the major nonrenewable fuel source part of oil sands. When bitumen incorporates with asphaltines a solid is formed that is useful for paving roads.

RTFOT simulates the consolidated effects of warm and also air on a thin movie of bituminous binder. The procedure is planned to mimic the ageing that occurs throughout the mixing as well bitumen 60/70 as transportation procedure for hot mixtures. For leading grade binders a practical correlation with the bitumen aging throughout asphalt mix manufacturing is reported.

In 1903, American Society for Testing of Products (ASTM) took on the grading of bitumen with infiltration testing at 25 ° C . The lower penetration value suggested the harder bitumen, while the higher infiltration value indicated the softer bitumen. The infiltration based grading system continued till 1970 and the very same proceeds also today in many nations including India.

When extracting it, a great deal of warm and initiative need to be made use of to update it to a better item. Although bitumen is difficult to draw out from the ground, it can bubble naturally to the surface of the Earth in petroleum seeps.

However, the majority of the bitumen drawn out from Canada's oil sands is updated into synthetic petroleum as well as sent out to refineries for conversion right into a full range of petroleum items, consisting of fuel. Asphalt bitumen is a binding natural product made from the by-products of refined petroleum. It is utilized bitumen grade 80 100 price in roadway construction due to the fact that it is easy to generate, reusable, non-toxic, and a strong binder. is suitable for road construction and for the asphalt sidewalks with exceptional homes.

This type of bitumen utilized in the manufacture of warm mix asphalt for bases and also putting on programs and the major use of this item is used in the road in light regions. iranian bitumen is supplied throughout the presses of oxidation of vacuum cleaner base in bitumen manufacturing systems. Because of its medium air blowing as well as infiltration, it is used in moderate areas. Bitumen is a low-grade of crude oil which is made up of complex, hefty hydrocarbons. In an oil storage tank, bitumen is a thick, viscous liquid as well as should be extracted from the ground.

http://shaboxes.com/author/fuentesbowers15/

These seeps are locations where nonrenewable fuel sources and oil items leakage out of the Planet as opposed to being trapped deep listed below the ground. Furthermore bitumen uae manufacturers, bitumen is the major nonrenewable fuel source part of oil sands. When bitumen incorporates with asphaltines a solid is formed that is useful for paving roads.

RTFOT simulates the consolidated effects of warm and also air on a thin movie of bituminous binder. The procedure is planned to mimic the ageing that occurs throughout the mixing as well bitumen 60/70 as transportation procedure for hot mixtures. For leading grade binders a practical correlation with the bitumen aging throughout asphalt mix manufacturing is reported.

How is bitumen Created?

In 1903, American Society for Testing of Products (ASTM) took on the grading of bitumen with infiltration testing at 25 ° C . The lower penetration value suggested the harder bitumen, while the higher infiltration value indicated the softer bitumen. The infiltration based grading system continued till 1970 and the very same proceeds also today in many nations including India.

What is bitumen used for?

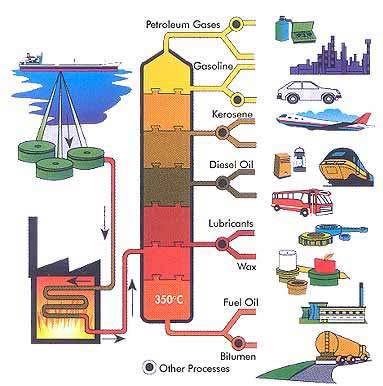

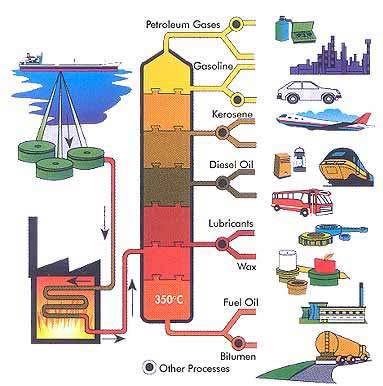

Petroleum Bitumen, normally called “Bitumen” or “Asphalt” is produced by refining crude oil. Used as a binder in road-building products, it is a very viscous, black or dark brown material. Finally, Bitumen is obtained by vacuum distillation or vacuum flashing of atmospheric residue from the vacuum distillation column.

They should halt construction on #TMX because there’s too big a question on its economic viability going forward. As countries like Russia and Saudi Arabia madly increase production as oil demand decreases, no one will want bitumen oil.

— Chris Harris (@ChrisHarrisBC) April 2, 2020

- This grade of Bitumen is generally utilized in the manufacture of warm mix asphalt for bases as well as wearing training courses.

- is a conventional penetration grade Bitumen typically made use of as a Paving Grade Bitumen suitable for roadway building and construction as well as for the production of asphalt sidewalks with remarkable properties.

What are the four major processing methods in manufacturing bitumen?

Asphalt concrete pavement mixes are typically composed of 5% asphalt cement and 95% aggregates (stone, sand, and gravel). Due to its highly viscous nature, asphalt cement must be heated so it can be mixed with the aggregates at the asphalt mixing facility.

OPEC cuts production, world price increases and US fracking & Ab bitumen are economic. OPEC and Russia open spigots and we are where we are. ‘Twas ever thus.

— Theseus’ Ship (@TheseusSchiff) April 1, 2020

When extracting it, a great deal of warm and initiative need to be made use of to update it to a better item. Although bitumen is difficult to draw out from the ground, it can bubble naturally to the surface of the Earth in petroleum seeps.

However, the majority of the bitumen drawn out from Canada's oil sands is updated into synthetic petroleum as well as sent out to refineries for conversion right into a full range of petroleum items, consisting of fuel. Asphalt bitumen is a binding natural product made from the by-products of refined petroleum. It is utilized bitumen grade 80 100 price in roadway construction due to the fact that it is easy to generate, reusable, non-toxic, and a strong binder. is suitable for road construction and for the asphalt sidewalks with exceptional homes.

This type of bitumen utilized in the manufacture of warm mix asphalt for bases and also putting on programs and the major use of this item is used in the road in light regions. iranian bitumen is supplied throughout the presses of oxidation of vacuum cleaner base in bitumen manufacturing systems. Because of its medium air blowing as well as infiltration, it is used in moderate areas. Bitumen is a low-grade of crude oil which is made up of complex, hefty hydrocarbons. In an oil storage tank, bitumen is a thick, viscous liquid as well as should be extracted from the ground.

http://shaboxes.com/author/fuentesbowers15/